Vikarta Herbals merges traditional Ayurvedic wisdom with modern innovation to offer top-tier herbal and Ayurvedic products. The company focuses on purity, sustainability, and maintaining the highest standards of quality in every product. Their offerings capture the healing power of nature.

Distillation Process: Crafting Purity at Every Step

The distillation process is the heart of Vikarta Life Sciences’ production. Raw materials enter specialized vessels, where the team locks them in with a head-locking mechanism to maintain airtight conditions. The boiling phase begins, lasting about an hour, allowing raw materials to release essential properties through steam.

The steam travels through connecting pipes into a chiller unit for cooling before further processing. The oil separator then carefully separates hydrosol and essential oils. This meticulous process, including chilling and separation, lasts 7 hours, yielding 30 liters of finished product. The factory uses vessels of various sizes—25 liters, 50 liters, and 100 liters—to accommodate production demands while ensuring top-notch quality.

Research & Development Lab: Innovation at the Core

The R&D Lab at Vikarta Life Sciences drives continuous product innovation. It develops new herbal offerings while ensuring safety and effectiveness. The process starts with 100g samples, and if successful, bulk preparation begins.

A moisture analyzer checks the wetness in oils, while dryers remove excess moisture. Sedimentation is monitored to prevent degradation. For creams and lotions, consistency tests ensure uniformity and performance.

Formulation involves several phases: the water phase, oil phase, and cooling phase. Ingredients mix in a heating machine at temperatures between 60 to 70 degrees Celsius. A double-boiling method ensures gentle separation before blending. Afterward, the product cools, preservatives are added, and the pH level is tested to ensure it stays between 4.5 and 5.5. Finally, a visual inspection ensures that the product meets color, texture, and appearance standards.

Machines Used in the R&D Lab:

- Moisture Analyzer: Measures moisture content in oils and powders.

- Powder Blender: Blends powders uniformly.

- Hot Air Oven: Dries and processes materials.

- Incubator: Maintains controlled environments for samples.

- Autoclave: Removes dust particles from products.

- Electronic Balance: Provides precise weight measurements.

- Centrifuge: Separates sediment from liquids.

- Viscometer: Measures viscosity of creams and lotions.

- Water Bath: Gently heats ingredients using a double-boiling method.

- Heating Mantle: Heats liquids to specific temperatures.

Cream Blending & Filling and Wrapping: Precision and Consistency

Cream blending begins with loading ingredients into a blending machine with a 50-kilogram capacity. The machine ensures the cream’s texture remains consistent and uniform. After blending, the cream transfers to a tube-filling machine, where it fills tubes with accuracy, minimizing waste.

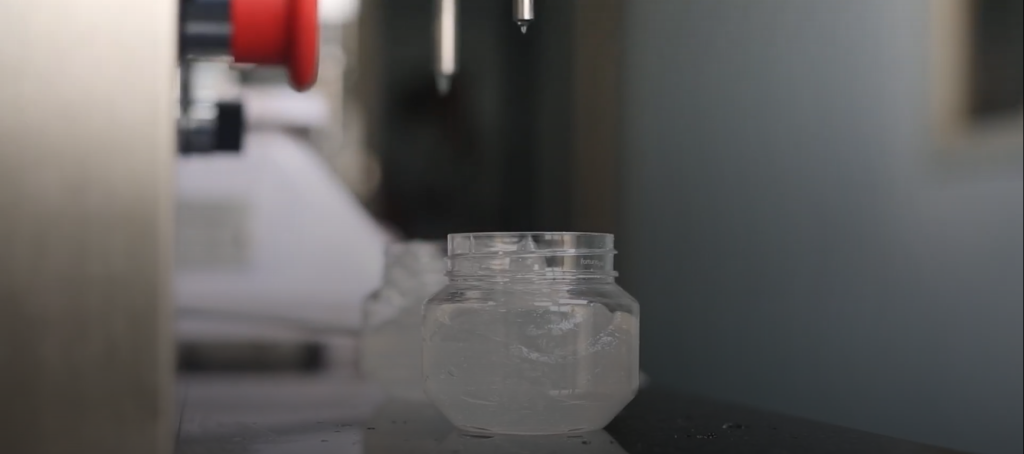

The filled products undergo packaging and sealing. A printing machine customizes packaging by printing labels and branding. A sealing machine then secures the product with heat pressure. Finally, a liquid filling machine dispenses accurate weight into containers.

RM Soap Unit: Crafting Herbal Soaps with Precision

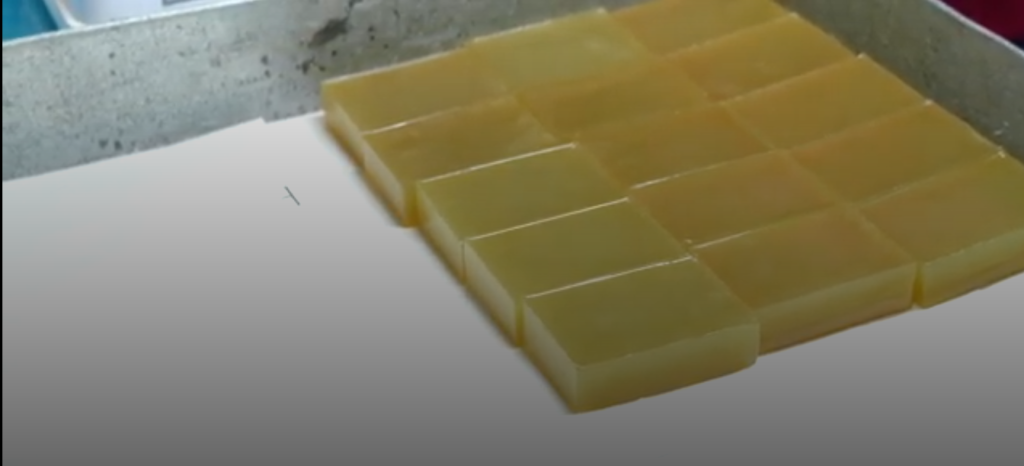

Vikarta Life Sciences’ RM Soap Unit produces herbal soaps and shampoos. A Cube Heater melts the soap and shampoo base, which is poured into molds. In the oil mixing process, the double-socket kettle paste mixing machine ensures thorough mixing at the required temperature.

Fragrances blend with the soap base for 20 to 30 minutes, achieving uniform consistency. Afterward, the product undergoes grunching for 1 hour. The mixture then goes through shape conversion and finally gets punched into accurate soap shapes.

The unit produces 100 to 150 soaps per hour, ensuring consistent output and high standards.

Pre-Process Area: Ensuring High-Quality Herbal Powders

The pre-process area prepares herbal powders. A Two-Stage Pulverizer and Chilli Cutter break down raw materials. The Powder Machine turns them into fine powders, up to 70 microns in size. Sieving and refinement through mesh sizes of 60, 80, 100, and 200 microns guarantee the desired texture.

After sieving, powders are filled into packets. The machine fills 800 packets of 100g each and 900 packets of 50g each per hour.

Final Stage: Dispatching Herbal Products for Delivery

Once processed and packaged, products are prepared for dispatch. Vikarta Life Sciences guarantees each step—raw material processing, product formulation, and packaging—meets the highest quality and sustainability standards.

What They Provide to End Customers and How to Reach Them

Vikarta Life Sciences offers a diverse range of herbal products, including essential oils, creams, lotions, herbal powders, soaps, and shampoos, all crafted to improve health and wellness naturally. Customers can experience the benefits of premium-quality Ayurvedic formulations designed for sustainability and effectiveness. To purchase their products or learn more, customers can visit their website, connect through social media platforms, or reach out via customer service helplines. Retail outlets and online marketplaces also stock their offerings, ensuring easy access for all.